The Real Cost of Staying Manual

The Real Cost of Staying Manual: Why “Too Expensive” Is the Wrong Question

Introduction: Why the Monthly Fee Isn’t the Real Cost

When NDT service companies consider moving from paper and spreadsheets to a digital platform, one objection comes up repeatedly: “It costs too much.”

It’s natural to focus on the monthly subscription fee. After all, inspection companies run lean, and margins can be tight. But focusing only on the software cost ignores the hidden expenses of staying manual, costs that don’t appear on invoices but show up in wasted time, lost revenue, and higher risk.

The real question isn’t “How much does a digital platform cost?” It’s “What is the cost of continuing without one?”

The Hidden Costs of Manual Processes

1. Time lost to paperwork

Inspectors often spend 2 to 3 hours after a field job transcribing handwritten notes into Excel or formatting reports in Word. For a 10 person company, even 2 hours per inspector per week adds up to 1,000+ hours per year lost to paperwork, the equivalent of half a full time employee doing nothing but administrative work.

That’s not inspection work. That’s not billable time. That’s pure overhead.

Industry Expert Insight:

“Admin tasks take up 30% of an average technician’s working hours — slightly more than the 29% they spend delivering their actual services.”

— Salesforce “3 Field Service Trends Today’s Leaders Need to Know”

2. Errors and rework

With manual data entry, mistakes are inevitable. A missing weld ID, a transposed measurement, or an incorrectly transcribed reading can delay projects, trigger re inspections, and frustrate clients. The cost isn’t just internal time, it’s also reputational damage and potential liability.

3. Compliance risk

NDT inspections exist to prove safety and compliance. Paper forms and spreadsheets are harder to audit, easier to lose, and more prone to inconsistency. A failed audit or lost certification record can result in fines, liability exposure, or worse: loss of client trust and future contracts.

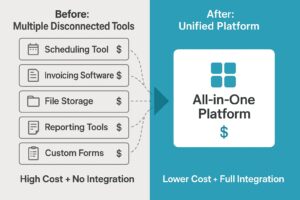

4. Multiple disconnected tools

Most companies that aren’t on a unified platform are already paying for a patchwork of solutions: scheduling software, quoting apps, invoicing systems, file storage subscriptions. Each one comes with its own monthly fee, and none of them talk to each other.

When you add up these hidden costs, the subscription fee for a purpose built digital platform often looks small by comparison.

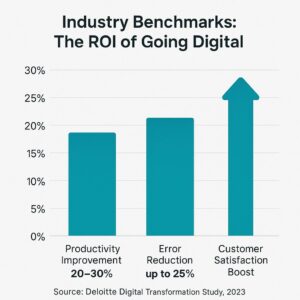

Industry Benchmarks: The ROI of Going Digital

Studies across field service and inspection heavy industries show consistent results:

-

- 20 to 30% productivity improvements once workflows are digitized

For a 10-person shop, that’s reclaiming 200-300 hours per year, enough to take on 2-3 more projects without hiring.

- 20 to 30% productivity improvements once workflows are digitized

-

- Error reduction of up to 25% when reports are standardized and automated

Fewer callbacks, less rework, and happier clients who don’t have to ask for corrections.

- Error reduction of up to 25% when reports are standardized and automated

-

- Customer satisfaction improvements tied directly to faster reporting and easier record access

Same-day reports and client portals mean more repeat business and referrals.

- Customer satisfaction improvements tied directly to faster reporting and easier record access

Digital Transformation Impact:

“Companies implementing comprehensive FSM software report productivity increases averaging 24% within the first year.”

— Field Service Management Software Statistics (September 2025)

Consolidation = Direct Savings

Floodlight isn’t just another tool you’re adding to your tech stack. It replaces multiple disconnected systems with a single platform built specifically for NDT:

- Scheduling → Eliminate standalone dispatching tools

- Quoting & invoicing → Replace general purpose accounting add ons

- Reporting → Remove the endless Excel/Word formatting cycle

- Customer portal → No need for separate file sharing subscriptions

This consolidation means you’re not just paying for software, you’re eliminating redundant costs and gaining integrated workflows that actually talk to each other.

Industry Analyst Perspective:

“Organizations that consolidate their technologies and shed their point solutions see cost savings almost immediately, as well as organizational and personnel efficiencies in the long run.”

— Imagine Software

What Digital Costs vs. What Manual Costs

When you’re weighing the decision to go digital, it helps to see the real numbers side by side. Below is what companies typically spend on software versus what they’re already losing to manual processes, broken down by company size.

Here’s the breakdown based on your company size:

| Company Size | Software Cost/Year | Manual Waste/Year | Net Savings |

|---|---|---|---|

| 10-50 inspectors | $7,800-$45,000 | $88,000-$500,000 | $43,000-$492,000 |

| 50-100 inspectors | $45,000-$90,000 | $438,000-$1,000,000 | $348,000-$955,000 |

| 100-500 inspectors | $90,000-$450,000 | $875,000-$5,000,000 | $425,000-$4,910,000 |

| 500-1,000 inspectors | $450,000-$900,000 | $4.4M-$10.0M | $3.5M-$9.6M |

| 1,000-2,500 inspectors | $900,000-$2.25M | $8.8M-$25.0M | $6.6M-$24.1M |

| 2,500+ inspectors | $2.25M+ | $22M-$25M+ | $19.8M-$22.8M+ |

Bottom line: The software typically costs about 10-15% of what you’re already wasting on manual processes. The other 85-90% goes straight back into your business.

The real question: Would you rather keep losing $100,000+ per year to inefficiency, or spend $10,000-$30,000 to fix it?

What Happens If You Wait

Here’s what’s happening right now while you’re staying manual:

- Your competitors are delivering same-day reports. How many repeat customers are you losing?

- Asset owners are demanding digital portals. Some are already cutting manual companies from their approved vendor lists.

- Auditors expect digital records. Paper files and spreadsheets don’t cut it anymore.

- Buyers want digital companies. If you’re thinking about selling in the next 5-10 years, staying manual lowers your company’s value.

The longer you wait, the further behind you fall.

Competitive Reality:

“73% of consumers will switch to a competitor after multiple bad experiences, and more than 50% will switch after only one bad experience.”

— Zendesk Customer Service Statistics 2025

Case Example: Two Companies, Different Trajectories

Consider two 20 person inspection firms:

Company A (stays manual):

Inspectors spend ~6 hours per week on paperwork. Over a year, that’s ~6,000 hours lost, equivalent to 3 full time employees doing nothing but admin work. Reports often take days or weeks to finalize, causing frustration for clients as well as causing delayed payment on work performed. Clients complain about delays.

Company B (goes digital):

Inspectors log results directly in the field using tablets. Reports are generated automatically. Paperwork hours drop by 50%. Customers receive reports same day or next day. The company looks more professional, wins more repeat contracts, and improves margins.

Company B doesn’t just save thousands of hours annually—they also look more professional to clients, which translates into more contracts and higher margins.

Real World Impact:

“After implementing digital inspection workflows, our average report turnaround time dropped from 3 days to same-day delivery. We’ve seen a 40% increase in repeat business directly tied to our faster, more professional reporting.”

— Operations Director, Mid-Atlantic Inspection Services (Anonymous client quote)

The Bottom Line

When NDT owners say “It costs too much,” they’re usually comparing a visible monthly fee to hidden costs they’ve learned to live with.

But here’s what we’ve learned from working with hundreds of inspection companies: the cost of staying manual always exceeds the cost of going digital. Always. It just shows up differently, in lost hours, frustrated clients, missed opportunities, and lower company valuations.

The NDT industry is at an inflection point. Asset owners are demanding digital access. Auditors expect standardized records. And the next generation of technicians won’t tolerate paper forms and spreadsheets the way the current generation has.

The companies that recognize this shift early and act on it, will be the ones that dominate their markets over the next decade. They’ll win more repeat business, command higher margins, and build companies that buyers compete for when it’s time to exit.

The companies that wait? They’ll eventually be forced to digitize anyway however by then, they’ll be playing catch-up to competitors who’ve already built a reputation for speed and professionalism.

You can lead this transition, or you can follow it. But you can’t avoid it.